"Beyond Metal, Toward the Zenith."

Zenithmet was established in 2015 (B.E. 2558) with a strong commitment from a group of engineers who aimed to elevate the standards of metal part manufacturing.

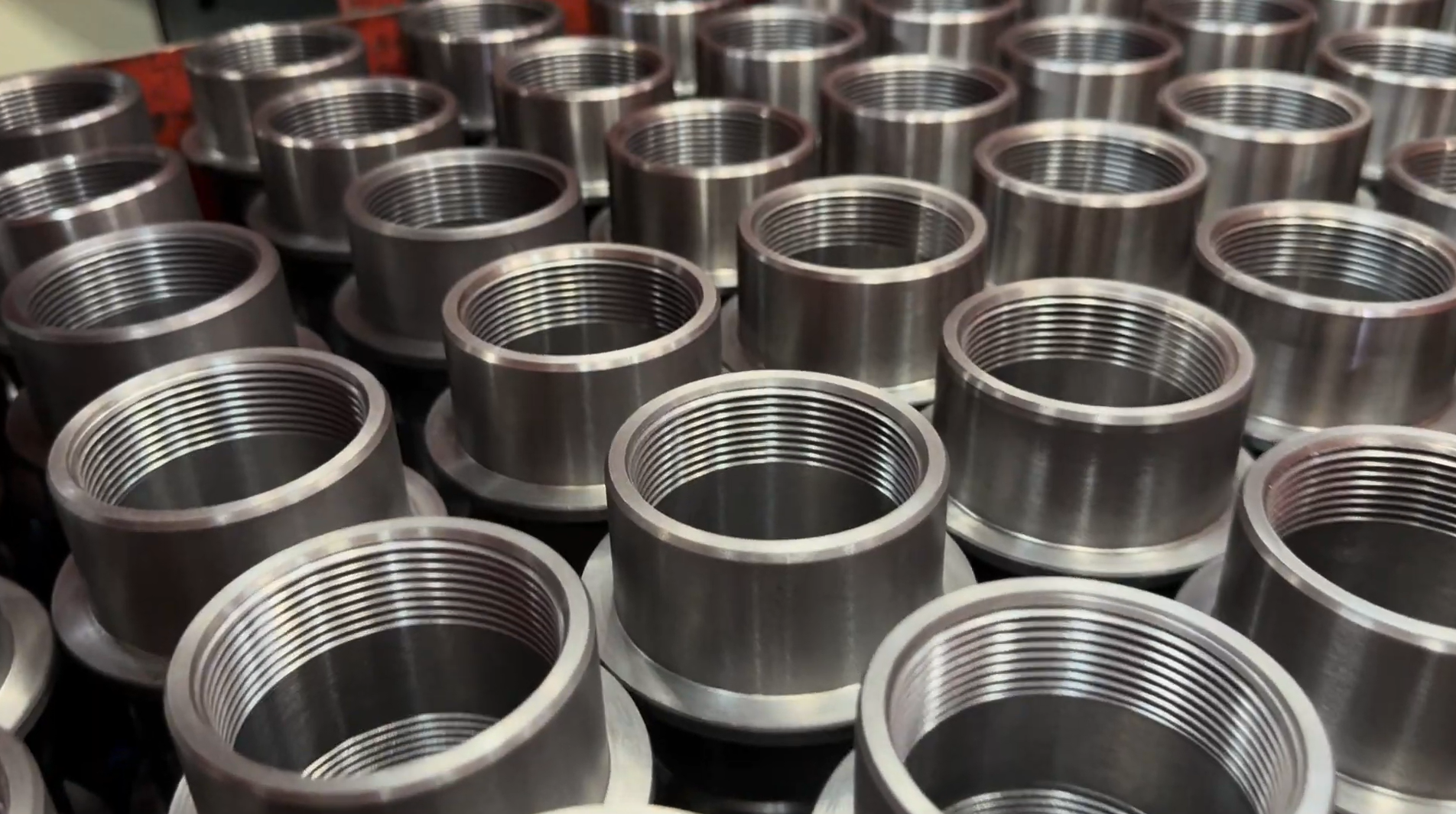

Starting as a small machine shop with only a few machines, Zenithmet has grown into a fully equipped precision machining factory. We now operate with advanced CNC machinery, modern inspection tools to ensure accuracy at every level, and a team of skilled professionals. Our experienced personnel are capable of producing complex components efficiently while maintaining high precision and consistent quality. We manufacture custom-designed parts for a wide range of industries, including automotive, machinery, and electronics.

"No matter who you are, Our Service Has No Limits."

BUSINESS PHILOSOPHY

01Specify the Requirement

Send us your drawing or 3D model so our team can thoroughly analyze your requirements and deliver a solution that perfectly meets your needs.

02Provide the Best Service

We will provide mold or part samples based on customer requirements to support evaluation and prepare a quotation plan that encourages long-term collaboration.

03Provide a Sample & Trial Mold

We strictly adhere to the agreed-upon plan — ensuring quality, timeline, and details — to maximize customer satisfaction. Samples are provided for review before mass production begins.

04Production

We are committed to manufacturing every mold and component to the highest standards of quality and efficiency, ensuring every batch reaches our customers in perfect condition.

05Track the quality of Product

We monitor and control the quality of every product to meet our standards, and we take full responsibility in addressing any issues related to the work we deliver.

Turning Machine

Feature

- Chunck 8 inch and 10 inch

OKUMA / GENOS L2000-e X = 165 Z=245

DMG MORI / DMU250 Mono Block X = 735 Y = 650 Z = 560

MC

Machining Center Machine

Feature

- Our CNC machines support both 3-axis and 5-axis operations , enabling the production of complex and highly precise components.

Quality Control Equipment

Coordinate Measuring Machine

with less than 1-micron accuracy

Quality Control device

with 20-micron accuracy

Quality Control device with

custom inspection solutions for each part

Machineing Parts

• Clip & Clamp Parts

• Compressor Parts

• Machine Parts

• Pump & Valve Parts

• Vehicle Parts

Pattern For Foundry

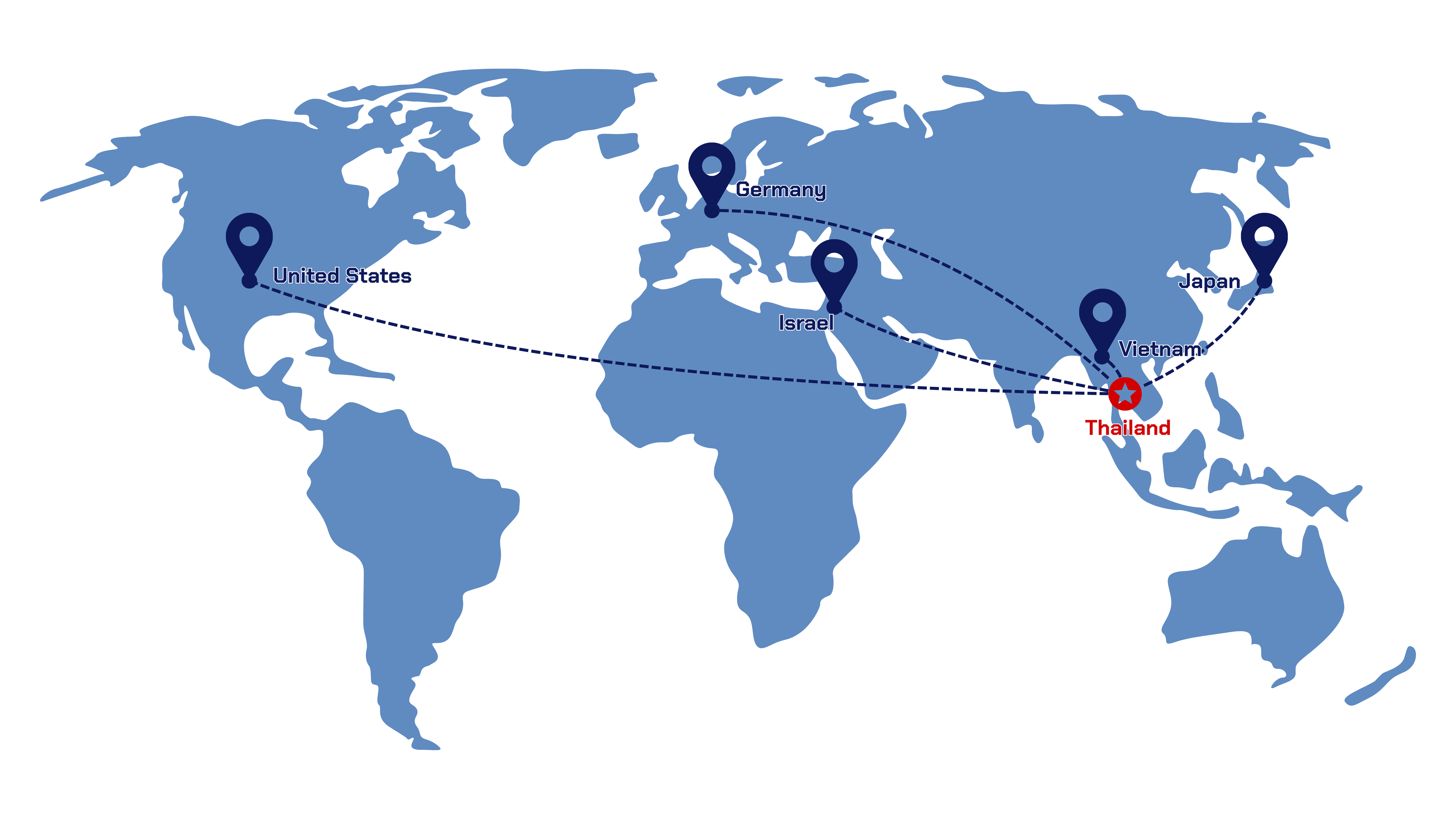

Partnership

United States

Germany

Israel

Vietnam

Japan

Thailand